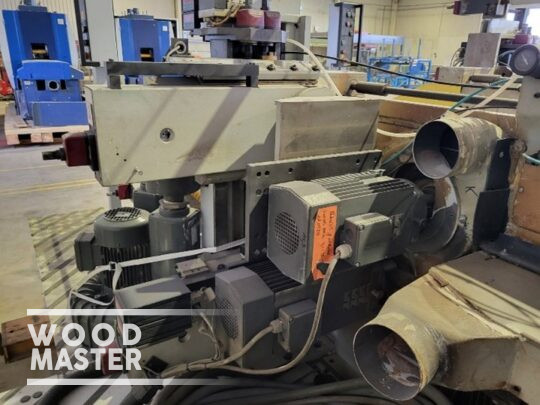

Machine details

| Manufacturer | Homag group |

|---|---|

| Year of manufacture | 1999 |

Machine description

Longitudinal side profiling machine for floor production.

The machine is sold as-is, where-is.

No guarantee is given.

Machine full description

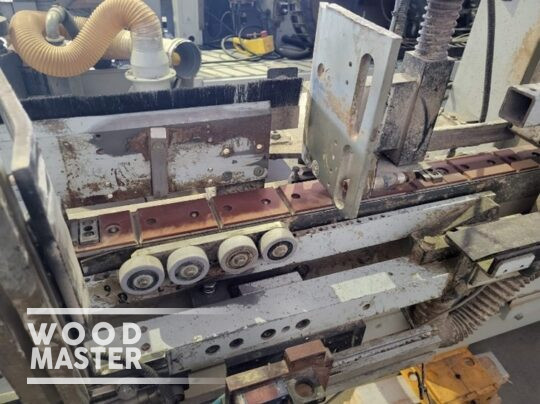

Longitudinal side profiling machine HOMAG, right side fixed, left side adjustable according to the width of the workpiece. The workpiece is transported through the machine by a special chain, with stepless speed regulation. The workpiece is pressed from above by a special 25 mm wide belt, the hight is adjusted according to the thickness of the workpiece.

HOMATIC controll with monitor, very convenient for work and creation of working programs.

Technical characteristics:

Stepless feeding speed: 10 – 66 m/min

Piece‘s thickness: 15 – 23 mm

Working height: 1085 mm

Min working width: 136 mm

Max working width: 1000 mm

Width of the feeding chain: 60 mm

On the right side of the machine is a feed ruler, adjustable. Spring-loaded rollers on the left side, for pushing the workpiece to the right.

The first milling unit, one on the left, one on the right. Motor horizontal, 8.1 kW, 100 Hz, 6000 min-1, can be tilted. Rotation directions can be switched, max. tool diameter 200 mm, motor shaft 40 mm, electronic display of vertical and horizontal position.

Second milling unit, one on the left, one on the right. Motor 8.1 kW, 100 Hz, 6000 min-1, can be tilted. Rotation directions can be switched, max. tool diameter 200 mm, motor shaft 40 mm, electronic display of vertical and horizontal position.

The third milling unit, one on the left, one on the right. Motor 6.6 kW, 100 Hz, 6000 min-1, can be tilted. Rotation directions can be switched, max. tool diameter 200 mm, motor shaft 40 mm, electronic display of vertical and horizontal position.

Fourth milling unit, one on the left, one on the right. Motor 6.6 kW, 100 HZz, 6000 min-1, can be tilted. Rotation directions can be switched, max. tool diameter 200 mm, motor shaft 40 mm, electronic display of vertical and horizontal position.

Fifth milling unit, one on the left, one on the right. Motor 6.6 kW, 100 Hz, 6000 min-1, can be tilted. Rotation directions can be switched, max. tool diameter 200 mm, motor shaft 40 mm, electronic display of vertical and horizontal position.

Workpiece cleaning unit, one on the left, the other on the right.

Machine No. 0-203-07-4309.

Compressed air required 6 bar.

Safety requirements CE.

en

en Lietuvių

Lietuvių