Machine details

| Manufacturer | Maggi |

|---|

Machine description

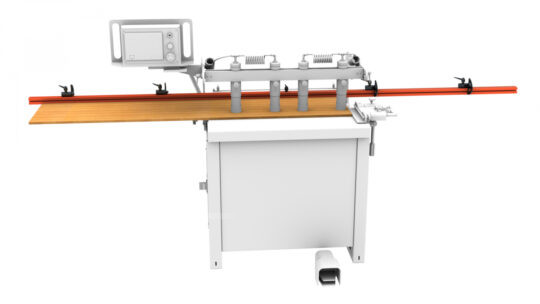

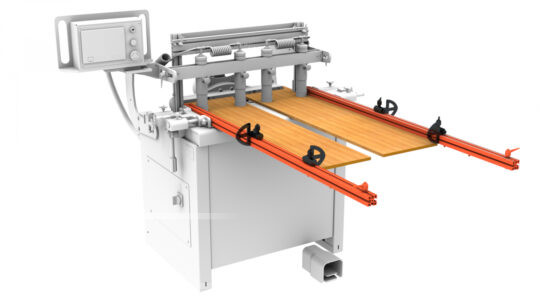

Multiple spindle one head drilling machine

Machine full description

TECHNICAL FEATURES

Quick-change spindles 32 mm interaxis. Electronic selection of boring height, depth and boring angle from 0° to 90°. Well-dimensioned working table made of steel. Ready to be connected to a dust-collector. Manufactured according to EC standards.

STANDARD EQUIPMENT

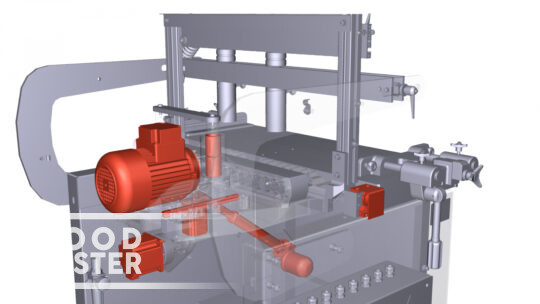

n.1 – 2HP Motor + linear actuator for boring-head tilting

n.2 stepper motors for the vertical and horizontal movement of the boring head

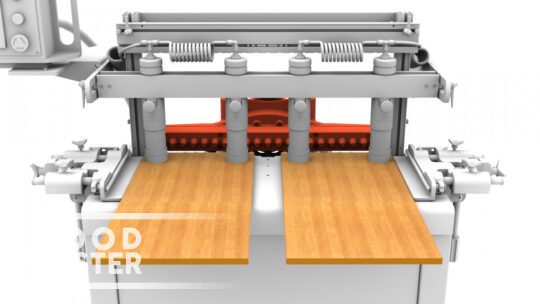

n.2 patented safety hold-down clamps

n.5 quick-change chucks

n.2, 1500 mm long, aluminium fences, with 4 ref. stops

n.2 removable side-fences on working table, adjustable on high-precision numeric counters

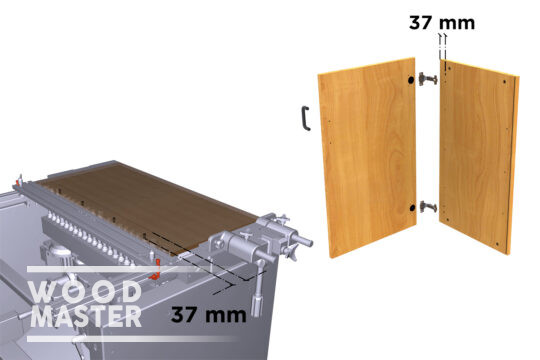

n.2 fixed ref. stops at 37 mm for hinges

Rear fence having 300 mm max. stroke

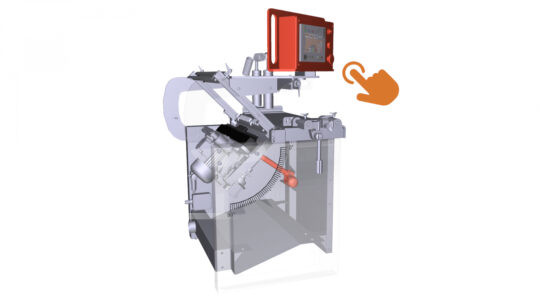

Ergonomic control panel, color 7″ touch-screen, PLC for the electronic selection of the boring parameters

“Linux” Operative System

Up to 1.000 working programs storable

USB and Ethernet ports

Package: stackable carton box

Ready to be connected to a dust- collector

Manufactured according to EC standards

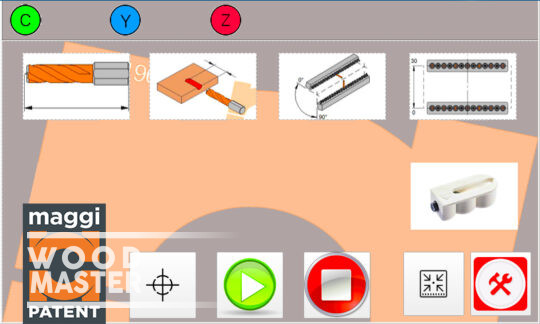

SIMPLE, ELECTRONIC, UNIQUE

Thanks to the “touch-, icon-based”, patented System, for the electronic selection of boring height, depth and boring angle over a PLC; the set-up is easy and intuitive and it does not require any specific programming skills.

HIGH-QUALITY END PRODUCTS

The high-precision movement of the NC axes, driven by stepper motors and encoder; as well as the well-balanced and even movement of the boring head, driven by a centered motor and sliding along linear guides and ball bearings, ensure an extremely accurate drilling process, and high-quality end products

QUICK SET-UP : CLICK AND GO!

Electronic selection and saving of the drilling parameters ( Up to 1.000 programs storable ) allow a reduction of the set-up time by 80%, making this machine two times faster than any other single-head boring machine of the same category.

PERFECT PANEL JOINTS

The ref. side fences, adjustable on numeric counters, always represent a precise reference point, quick to set-up, and guarantee perfect parallelism of the drilling operations.

VERSATILE

It drills at any angle between 0° and 90°. The selection of the boring angle is electronic over a touch screen

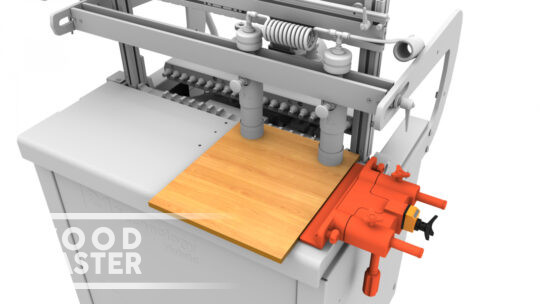

SAFE PANEL HOLD-DOWN

The quick-positioning, safety, hold-down clamping units ensure the greatest stability and steadiness of the working piece during the working cycle and the highest accuracy of the drilling process

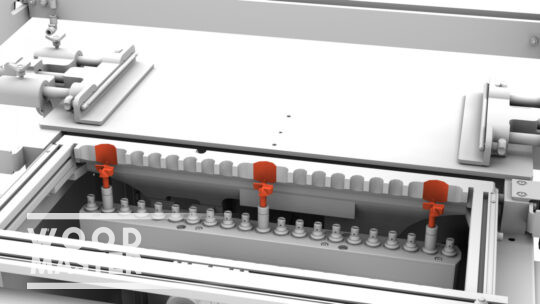

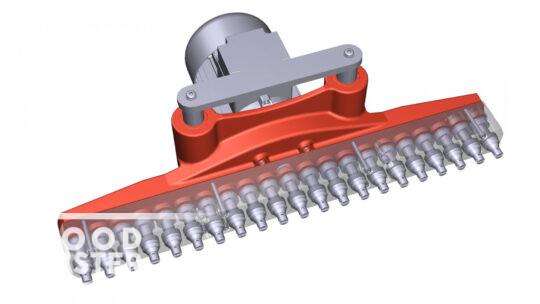

TOP-OF-THE-RANGE BORING-HEAD

Made of aluminium with internal gears made of rectified steel; well-dimensioned holder plate and centered motor for the highest balance, sliding on guides and sleeve bearings for an even vertical and horizontal movement to give You a top-performance, always!

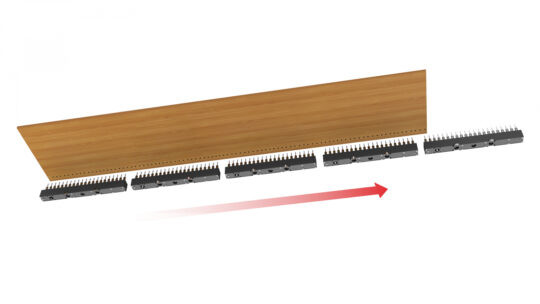

FAST HORIZONTAL DRILLING

Thanks to the 640 mm interaxis and the large working table, You can process 2 panels having 316 mm width at the same time

FAST VERTICAL DRILLING

You can process 3000 mm – long sides in 5 working cycles

QUICK AND ACCURATE PANEL POSITIONING

Thanks to the two aluminium fences 1500x 80 mm with 4 reference stops,( two are included, two are options)

QUICK AND ACCURATE PANEL POSITIONING

Thanks to the two aluminium fences 1500x 80 mm with 4 reference stops,( two are included, two are options)

REAR FENCE

The rear fence, 300 mm stroke, allows to drill holes right in the middle of wardrobe side-panels, without using the long fence.

FIXED STOP FOR HINGES

The 37 mm fixed ref. stop is extremely useful to drill fixing holes for the hinges on side panels.

SPECIAL DESIGN TO WORK WITH LARGE-DIAMETER DRILL-BITS

The comb has been designed so as to have 3 fixed positions where You can use cutter-drill bits of large diameter, without any further adjustment of the boring head.

SOLID STRUCTURE

Made of steel, built to last, eco-friendly, rust-resistant powder coating.

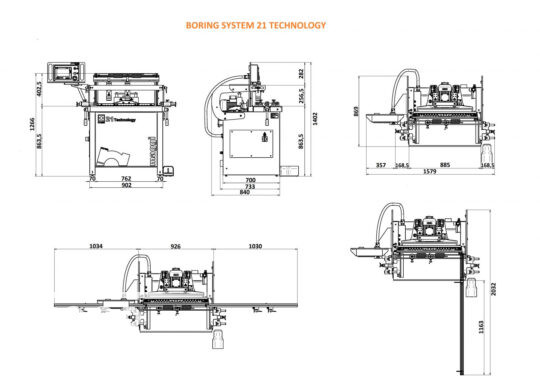

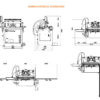

TECHNICAL CHARACTERISTICS:

Spindles N. 21

Left and right spindles N. 10 sx – N. 11 dx

Spindle interaxis 32 mm

Total interaxis 640 mm

Max. tool diameter 40 mm

Max. boring depth 65 mm

Max boring height 55 mm

Height of working table 860 mm

Dimensions of the working table 885 x 349,5 mm

Max. panel thickness (optional*) 60 mm (130 mm *)

Max. panel dimensions 900 x 3000

Motor HP 2 / KW 1,5 – RPM 2800

Stepper motor 1 nema 24, 3.2 Nm, 4.2 A, 800 g/cm^2

Stepper motor 2 nema 34, 4.4 Nm, 5.6 A, 1050 g/cm^2

Linear actuator max 6000 N, 12 mm/s, RPM 5000, max 24 A

Standard pneumatic pressure BAR 6/ 8

Air consumption per working cycle 5 NL

Dust collection hood diameter 80 mm

en

en Lietuvių

Lietuvių