Machine details

| Manufacturer | Kadis |

|---|---|

| Year of manufacture | 2015 |

Machine description

Finger jointing line, consisting of routing machine and press.

The machine is sold as-is, where-is.

No guarantee is given.

Machine full description

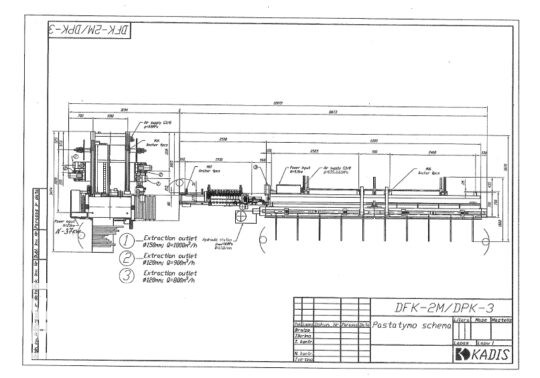

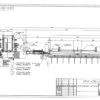

Automatic finger jointing line for wooden elements consists of:

Two side finger jointing machine DFK-2M;

Automatic two position hydraulic press DPK-3A.

Two side finger cutting machine DFK-2MP consisting of:

– Loading table;

– Unloading table;

– Two cutting aggregates for finger cutting;

– Glue spreading aggregate;

FINGER CUTTING AGGREGATE DFK-2MP TECHNICAL PARAMETERS

– Pieces‘ parameters, mm:

– thickness 18…155 mm

– length 160…1100 mm

– Package‘s width 600 mm

– Feeding speed 4…20 m/min

– Capacity 3 packages/ min.

– Fingers‘ length 10/11 mm

– Diameter cutting spindle 50 mm

– Capacity routing motors 11 kW

– Capacity sawblade motors 6 kW

– Capacity installed 37 kW

– Compressed air required 0,7…0,8 MPa

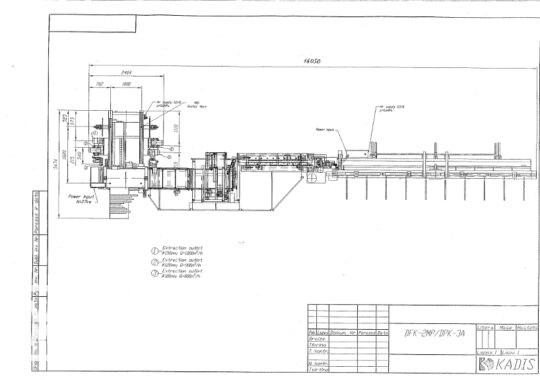

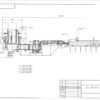

Automatic hydraulic press with two positions DPK-3A consists of:

– Pieces‘ loader;

– Longitudinal pieces‘ loader with inicial pressing, with measurement;

– Pieces‘ tilting aggregate.

PRESS DPK-3A TECHNICAL PARAMETERS

– Pieces‘ parameters, mm:

– width 40…155 mm

– height 18…80 mm

– length min 160 mm

– Max length after pressing: 6050 +50 mm

– Capacity up to 5 cycles/min

– Pressing force 90 kN

– Capacity installed 9,9 kW

Common length of the line 14500 mm

Weight of the line 6000 kg

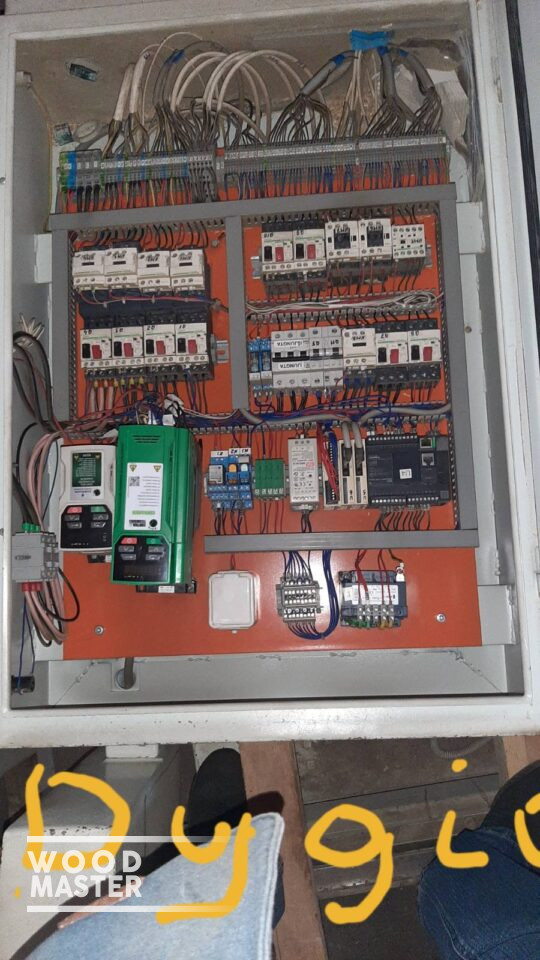

Press posess control unit, so some parameters may be set, like length of final product or cut to required lengths.

Press posess diferencial hydraulic cylinder for fine adjustment of pressing force. This is very important when pressing small pieces.

With tools.

The line is dismantled, ready for transportation.

EU safety regulations CE.

en

en Lietuvių

Lietuvių